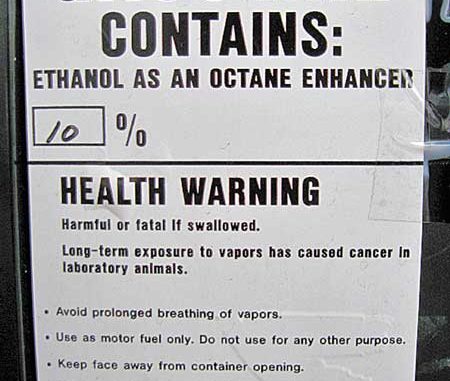

What in the world are they thinking? While we, the consumers — and the mechanics who have to keep our marine engines running — still haven’t figured out good ways to deal with the side effects of adding ethanol up to 10 percent into our fuels, the EPA and some legislators are considering upping the allowable level to 15 percent.

Yep, with a push that began in March, a pro-ethanol lobbying agency, Growth Energy, and more than 50 ethanol producers, began lobbying the EPA to increase the level of ethanol in gasoline. The initial comment period drew nearly 30,000 comments from concerned boaters, the marine industry, marina operators and many other boating groups, so the EPA extended the comment deadline to July 20.

Behind pushes by the Boat Owners Association of the United States (BoatUS) and the National Marine Manufacturers Association (NMMA), comments against the increase again came in large numbers.

The NMMA submitted a document with 40 pages of comments on why the petition to raise ethanol levels and any partial approvals — which would create dual fuel supplies and resulting confusion — should be denied. Now, the decision is up to the EPA, which has until Dec. 1 to approve or deny the petition.

The possibility of raising the allowed ethanol content in gas is not good news. Every mechanic I have spoken with in the past year said most of today’s fuel-system problems are caused by ethanol, and that covers mechanics who work on automobiles, trucks, outboards, lawnmowers, portable generators, leaf blowers or chainsaws. To a man, they believe the addition of ethanol to fuel creates situations that are detrimental to fuel systems and therefore to the engines. Representatives from the outboard manufacturers said their engines would operate fine on E-10 fuels but would have issues with higher ethanol concentrations.

With independent tests showing that the ethanol content of E-10 often approaches 20 percent as is, one can only wonder how high the actual concentration might creep if the standard is raised?

Most current engines and fuel systems are certified for use with E-10 (10-percent ethanol fuel), but even then, manufacturers warn about the need to replace fuel filters more frequently, use special 10-micron water-separating fuel filters, keep fuel tanks topped to prevent condensation and not store ethanol-blend fuels for any length of time. Another cost associated with using ethanol is increased maintenance and repairs.

Not only is ethanol not good for engines, it is expensive to produce, and many environmentalists claim the effects from growing the extra corn and the production process are roughly equally as harmful to the environment as the petroleum emissions it helps reduce.

Since ethanol-blend fuels have been forced on us, what can we do to make using them as painless as possible? The two biggest concerns with using ethanol-blend fuels have to do with the natural tendency of alcohol to attract and bond with water. If this was a fine, Tennessee sipping whiskey, that bonding with water would be fine. However, a fuel source must be ignited and burned to create energy, and water doesn’t burn. When fuel attracts water, it lowers the efficiency and sometimes even prevents it from burning at all.

The other negative is that when ethanol saturates with water, it becomes a cleaner, a solvent and corrosive — sometimes even to the point of separating from the gas as in phase separation. This leads to dissolving any deposits within fuel tanks and delivery systems, plus corroding many metal parts and dumping the corroded particles into the fuel as contaminants. While fuel-system components on newer engines are supposed to be safe, on older engines, the solvent created by the alcohol deteriorates seals, O-rings, fuel lines, plastic parts and such and sends them into the engine with the fuel, plugging filters and fuel systems.

For instance, solvents and corrosives have on occasion dissolved resins in plastic or fiberglass fuel tanks and dissolved fuel-line components, causing complete failure. Several prominent boat manufacturers have switched from fiberglass to metal fuel tanks, even though they were using resins that were supposedly ethanol safe. Unfortunately, we don’t have much experience with this additive and are still learning what havoc it can wreak.

In areas where ethanol-free fuels are not available, boat owners can do several things to help avoid phase separation and other pitfalls. The first is not to store fuel. The longer ethanol sits, the more likely it is to become contaminated with water and become phase separated. Running your boat tanks nearly dry on every trip is a possibility. If you can’t, follow the example of one person with whom I spoke. When his boat hasn’t been in the water for an extended period of time, or his trip wasn’t long enough to use all the fuel, he transferred the remaining gas from his boat to his truck and ran it rather than storing it. This is a great idea, but it is probably a little too difficult for most folks.

Storage treatments are another way to prolong the length of time fuel can be stored. Many fuel treatments are available, and most brands make some claim as to their effectiveness with ethanol-blend fuels. Some of them are real good, but some aren’t so good.

Several months ago, I was introduced to Sentry Fuel Treatments by my friend, C.A. Richardson of Flats Class TV (www.flatsclass.com). In addition to doing the TV show, Richardson and his partner, Ray Van Horn, guide several days a week and compete on several redfish and inshore tournament trails.

This past spring, they wound up with a tank of E-10 gas that had a high percentage of water. Their Evinrude E-TEC would start and run, but it sputtered and coughed badly with the high water content. Fortunately, they knew enough to purge the larger canister fuel (fuel/water separator) filter and were able to get through the day and back in, but had to purge the filter numerous times. After nursing the boat back to the ramp, they set about finding out what to do to get the problem fixed.

Someone suggested Sentry Fuel Systems.. Richardson called Suncoast Marine, an Evinrude dealer in the St. Petersburg, Fla., area that was familiar with the Sentry product line and recommended it.

“I added the recommended amount of Sentry Gasoline Plus, and the problem was solved,” Richardson said. “I carry it with me everywhere I go. I try to always buy ethanol-free gas, but when I’m forced to use gas with ethanol, I always add the Sentry and haven’t had any more problems.”

Dennis Mietz of Total Fuel Solutions manufacturers Sentry Fuel Treatments. He explained that the Sentry Fuel Treatments seek out water, separate it and microencapsulate it. This prevents the water from causing phase separation and corrosion with ethanol-blend fuels.

I don’t claim to be an expert, but I know what I have seen, done and heard. I’m pretty impressed with the Sentry Fuel Treatments line of products. I still don’t care for ethanol-blend fuel, but they make it a little easier to endure.

You can learn more about the effects of ethanol and Sentry Fuel Treatments at www.sentrytreatments.com. A few dealers in North Carolina are testing the products, and the list is growing. If you can’t find a dealer, you can order from the website.

Another way to inhibit problems caused by ethanol-blend fuel is to install 10-micron water-separator filters between the fuel tank and the motor. By adding these filters and changing them and the filters on the side of the engine frequently, most water and contamination can be removed and engine damage prevented. It isn’t cheap to keep changing filters, but it is far more inexpensive than rebuilding motors.

Be the first to comment