Downriggers provide a great way to get deep

Trolling offers a way to present baits to a lot of fish over a large area, but when fish aren’t at the surface, you must get your offerings down to them or you’ll have an empty fish box at the end of the day. Of the ways to get trolled baits below the surface, I believe downriggers are the most versatile.

Downriggers are those large reels with short, stout rods that are mounted on the gunwales or transoms of many fishing boats. The rod, or arm, as it is properly called, is stout to handle the strain of pulling a heavy lead ball or planer. Downrigger arms can be fixed at short or longer lengths, and some telescope to help with spreading lines.

Most downrigger reels are designed to hold 135- to 200-pound braided cable and all come filled. However, Cannon Tournament Series downriggers are designed so the owner can switch out to heavy monofilament line. The downrigger reel is calibrated to a counter that tells how much line has been removed from the spool, so depth can be calculated.

The line on a downrigger has a heavy duty snap swivel at the end to attach the weight or planer that pulls the line down. Planers rely on forward motion to dive, and many downrigger manufacturers recommend against using them because of extra stress they put on the downrigger and mount. Downrigger weights typically resemble a cannon ball with a fin, but some are flatter or resemble fish to cut through the water easier.

A release is attached to the downrigger line or ball, and the line from the lure runs to the release and then up to the rod and reel. The extra pull of a strike triggers the release, and the fisherman fights the fish on the rod and reel, without the extra drag of a trolling sinker or planer. The downrigger line is reeled in to be reset after landing the fish.

Freshwater fishermen have been using downriggers for more than a half-century, and the multiple-downrigger and multiple-line setups they use to fish for salmon, lake trout and other species are amazing. Many use up to six downriggers to troll 10 to 15 lines, and baits and lures rarely tangle.

Most North Carolina fishermen were introduced to downriggers as a means to slow-troll live baits at a set depth for king mackerel. Using frisky live baits presents a few issues with tangling, so most king mackerel fishermen only use one or two downriggers, and they typically troll a single live bait from each one.

Two primary categories of downriggers exist. With manual downriggers, the fisherman lets the line down to the desired depth and cranks it up after a strike. All electric downriggers will retrieve the downrigger line for you, and some will do more. Electric downriggers in the upper price range have an assortment of special features such as programmable depth, bottom tracking, variable depth jigging and releasing a minute electrical discharge into the water as a fish attractant.

Unfortunately, the caustic properties of saltwater and constant exposure to salt air can play havoc with electrical connections. Electric downrigger connections must be properly installed with all the spray shielding possible and connections maintained for corrosion prevention. They can be unique fish-catching tools when they work, but when they don’t work, they’re just in the way.

The braided cable that comes standard on downriggers doesn’t feel particularly abrasive to the touch, but if monofilament is dragged across it, the wire cuts it. That doesn’t bode well for king mackerel fishing when mono is the line of choice, and occasional wraps around the downrigger cable are commonplace. So fishermen started looked for a substitute downrigger line.

With the exception of the Cannon Tournament Series, downrigger manufacturers warn against using anything other than braided wire on downriggers. Size and stretch are their concerns. Mono was the first substitute, and it stretches, especially when wet. This isn’t bad while fishing, but at the end of the day, the stretched mono was wound on the reels, and when it dried and tried to return to its original length the extra stress was more than many spools could stand. It sometimes crushed or split them.

Some fishermen substitute superbraid lines for downrigger cable, as they are very strong, small in diameter and have virtually no stretch. Their diameter is one-third to one-half of similar-strength mono and smaller than similar-strength braided cable, which has its own problems. Many downrigger reels are multiple-piece, and braided line will sometimes get into the gaps between the pieces and spread them apart, which can crack the pieces and jam the reels.

Monofilament or fluorocarbon line of the same strength as the standard downrigger cable is larger in diameter and causes excessive blowback — deflection of the downrigger line due to the drag of it being pulled through the water. The smaller superbraids eliminate almost all blowback but are abrasive, maybe even more abrasive than the original braided wire.

I prefer monofilament for king mackerel fishing. Sometimes you just can’t react fast enough when a fish strikes, and it gets around a downrigger line. Mono has several unique properties and one of them, which I jokingly refer to as Murphy’s Law of Moving Mono, is that when two mono lines tangle or rub, the moving line will cut through the stationary line regardless of the difference in diameter. I’ve lost a few downrigger balls and releases, but I’ve landed some large kings because of this, and I think that’s a reasonable trade-off.

My downrigger setup leaves the original wire on the spool and adds 100 to 150 feet of 80- to 100-pound monofilament. The wire acts as a pad for the mono and helps cushion the downrigger spool. The lighter mono is the same diameter as the 135- to 150-pound braided wire that comes on downriggers and is plenty strong to hold a 10-pound downrigger ball. At the end of the day, I remove the downrigger ball and let out a little more line than was used at the deepest setting that day and then reel it back in slowly, with no pressure and layer it evenly on the spool.

I have sets of both Penn and older Cannon downriggers. This has worked well on the Penns with no further modifications. Cannon uses a two-piece spacer on the spool and occasionally, the stretched mono crawls over the edge and jams between the spacer and the spool. If allowed to continue, this will spread the spool until it cracks or jams in the downrigger body.

My fix for this isn’t pretty, but has worked well so far. I install a series of stainless steel bolts from side to side through the spool to tighten it together and prevent the mono from crawling over the edge of the spacer. This allows using mono on the older Cannons. If I was buying new Cannon downriggers, I would purchase Tournament Series models.

If you change the downrigger line on an electric downrigger with the auto-stop feature, be sure to check it before going fishing. Some auto-stop mechanisms create a ground in the water through the downrigger wire and stop when the ground is broken, and some use counters to stop. Monofilament counts well but doesn’t conduct electricity, and this prevents the ground type of auto stop mechanisms from working properly. Your owner’s manual or a quick check should tell you which you have.

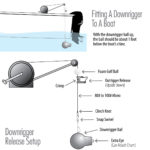

My final tip is to make the downrigger setup as simple as possible and adjust it to your boat. Proper adjustment leaves the ball just below the surface when the release is reeled to the end of the arm. The release is easy to reach, and the ball is stabilized in the water so it won’t swing and beat the side of the boat. My downrigger terminal gear is a foam practice golf ball, an outrigger release, a crimp and a snap swivel that are mounted on the downrigger line.

Drill a small hole in the foam golf ball. Begin at the bottom end and slide the ball onto the downrigger line. Next, slide the outrigger release on the downrigger line upside down, with the crimp between its ears. Last, tie the snap swivel to the end of the line. I prefer the Blacks RC 99 clip, but if it is difficult to find, the RC 100 outrigger clip or RC 95 downrigger clip will work with their mounting wire removed.

To fit the release, mount the downrigger and lower the ball until it is about a foot below the water or a foot below the water line if the boat is on a trailer. Slide the release clip, with the crimp between its ears and the foam golf ball up the line until the golf ball reaches the end of the downrigger arm and won’t go any farther. With the release holding the golf ball against the end of the downrigger arm, compress the crimp. This holds the release and ball in this position, with the downrigger ball just below the surface.

The ball won’t swing and bang the side of the boat when it is up, but is close enough to the surface to be out of the way. The release is slightly above the gunwale, where it is easy to clip in the line. The foam golf ball is a cushion in case you reel up the downrigger line fast and jam it into the downrigger arm. The ball should slide on the line and stay at the surface.

Be the first to comment